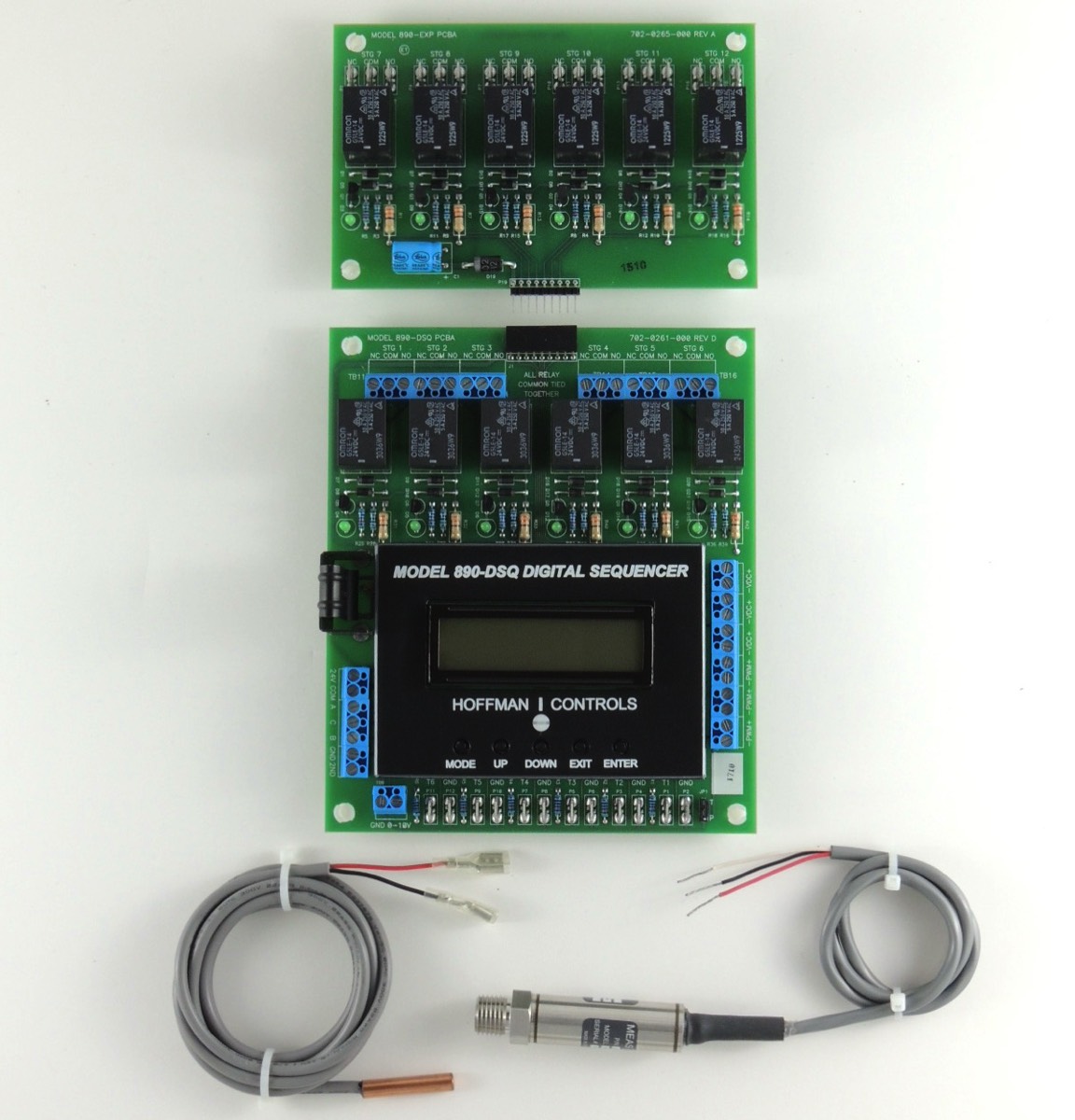

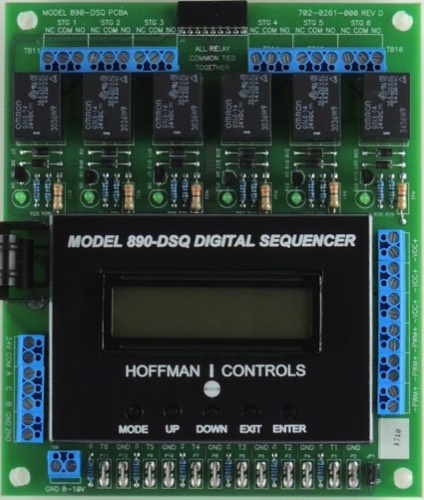

890-DSQ

Universal Sequencer and Modulator

The sequencer has six inputs which can be used to monitor temperature, pressure, or any resistance or voltage signal up to 5 VDC. There is also a 0-10 VDC input. The number and type of inputs can be set using a menu-based system. Temperature can be measured over a 0ºF to 115ºF range. Pressure can be measured up to a maximum of 1000 PSI (depending on sensor used). Multiple inputs can be combined using several options: highest value, average value, median value, or second highest value. An emergency on value can be set that will cause the output to run at maximum if that input value occurs on any input line.

The sequencer has two types of outputs: fixed relay stages and a variable modulating output used for EC motors or SCRs. For a traditional sequencer, only the fixed stages are used. Six fixed stages are included and up to 12 fixed stages are available with the addition of a piggyback board. Both the fixed stages and the variable output can be used to control a combination of fixed and variable loads. The controller intelligently applies a combination of fixed plus modulating outputs to achieve a continuously variable output, including adjustable hysteresis on the fixed stages. The variable stage output is available both as a PWM signal and as a 0-10 VDC signal. The DC output can be inverted to a 10-0 VDC signal. The variable stage output can drive up to nine EC motors or supply up to 90 mA to operate SCRs. The number of fixed stages and the ratio of the variable to fixed stage size can be set using the menu-based interface.

A Modbus RTU interface is included in the controller which allows all parameters to be set over Modbus and all present settings and current input and output values to be read over Modbus.

Input set points including on and off input values for each fixed stage can be set individually or can be determined automatically by giving the low and high span values and desired hysteresis. The controller can store up to two complete sets of set points and can switch between the two sets based on a contact closure.

Applications

- Control of a bank of condenser fans using liquid line temperature or pressure sensing to monitor head pressure. When using a bank of fans that includes fixed speed and variable speed, the control will modulate the variable speed fans to provide a continuously variable airflow across the condenser coil.

- Control of a bank of heating elements using temperature monitoring. When using a bank of heating elements that includes fixed stages and variable stages, the control will modulate the variable stages to provide a continuously variable output of the combined fixed and variable stages.

- Control of a bank of compressors consisting of fixed output compressors and possibly variable output compressors, thereby achieving a continuously variable output of the combined fixed and variable stages.

- Any control application which requires sequencing of fixed stages and possibly use of a variable stage to achieve continuously variable output.

Features

- A/C liquid line temperature or pressure sensing of up to six input sensors

- User selectable methods of combining input sensor values (max, average, median, second highest)

- Stepped output of up to 12 stages with settable hysteresis values (more than 6 stages requires piggy back board)

- Continuous (modulated) output that can be combined with stepped output to achieve continuously variable output

- Fixed stage outputs are low voltage pilot duty isolated relays with LED indicators

- PWM and 0-10VDC or 10-0 VDC outputs for control of up to nine EC Motors

- PWM can supply up to 90mA for control of SCR heaters

- All fixed stage set points and hysteresis can be digitally set by operator or can determined automatically using range and hysteresis values

- Two compete sets of set points can be stored with the controller using one or the other depending on a contact closure

- Loss of power auto recovery

- Relay stage LED indicators

- Large 32 character LCD screen for readout of values and setting parameters using a menu system

- Modbus RTU included so that all parameters can be set or read remotely and all input and output values can be read remotely

- Modbus baud rate, slave ID, and parity can be set using the menu system

Data Sheets and Instructions