MADE IN AMERICA

50 Years of Innovation

See you at the

2019 AHR Expo

Jan. 14-16, 2019

Atlanta

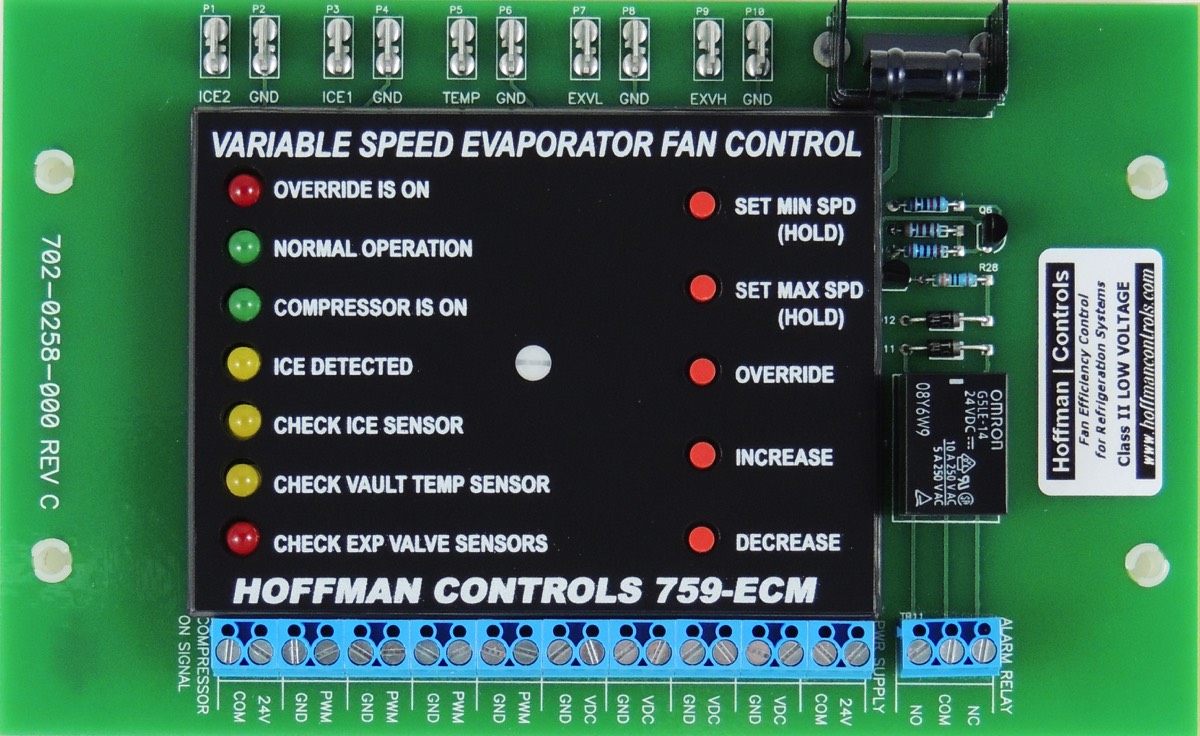

- For walk-in and reach-in coolers and freezers

- Continuously variable evaporator fan speed automatic control

- Maximum efficiency, reduced compressor run time, improved product shelf life

- PWM and DC outputs

- Multi-Motor Capable

- Compatible with all variable speed EC motors (ECM)

- This is a retrofit. Replace your fan (if needed) and the fan control input with the 759 and save energy. All necessary items supplied by Hoffman Control.

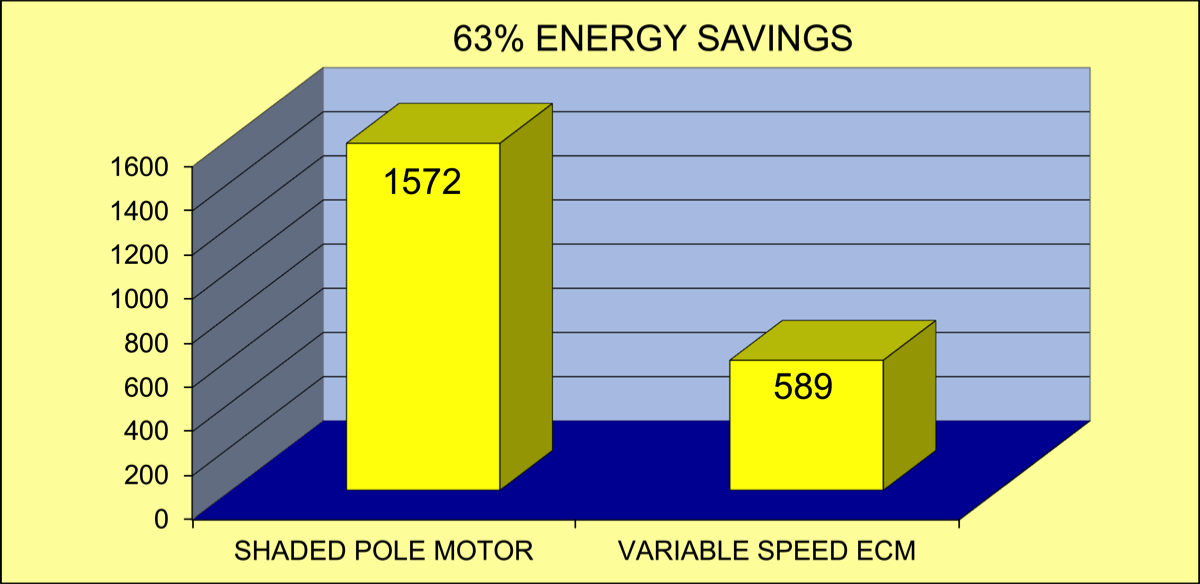

The chart above shows the average power consumption in Watts for a mid-temperature walk-in cooler as tested in our laboratory. This represents a 63% reduction in energy. Although other ECM environments demonstrate some reduction in energy compared to shaded pole motor evaporator fans, this controller has shown the most efficiency since it continuously optimizes the fan speed based on current operating conditions using an adaptive algorithm.

Other Featured Products

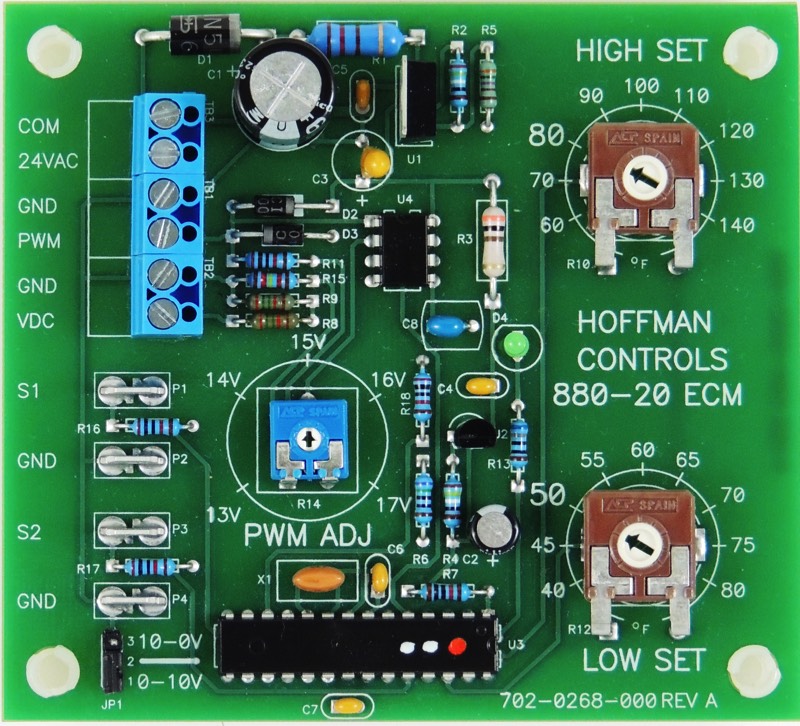

This electronic head pressure control modulates condenser fan motor speed thereby varying the air volume through the condenser. The control monitors the head pressure by sensing the sub-cooled liquid line temperature.

There are two temperature inputs and three outputs (PWM, 0-10 VDC and 10-0 VDC) to control the ECM or VFD variable speed fan motor.

Two temperature parameters can be set to optimize the range of fan speeds so that as the ambient temperature changes, the fan speed is varied in order to maintain the correct head pressure.

This improves system performance while saving energy and eliminating compressor slugging. The non-invasive temperature sensors require no system penetration.

If you need to control multiple motors, or have more or other input sensors, or have Modbus communication, we've got a product for that also.

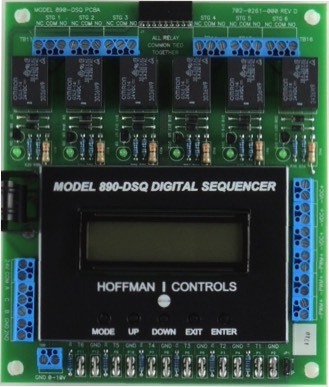

- Operate up to 12 stages of fans, compressors, or heaters

- Continuous output variation possible with one variable unit added to the mix

- MODBUS RTU communication with building automation systems

- Up to six sensors for monitoring inputs with combining options

- Menu system allows easy set point adjustment including hysteresis

- Secondary set of set points can be used based on an input contact closure

- 32 character LCD display

- 12 relay outputs plus modulating output (PWM and 0-10 VDC or 10-0 VDC)

- Inputs can be temperature, pressure, 0-10 VDC, or contact closures

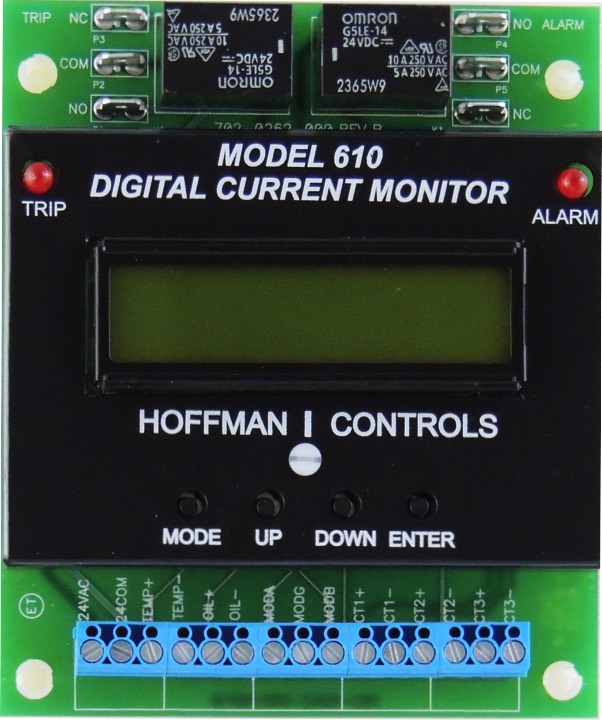

- Protects single phase and 3 phase motors from current draw problems

- Uses current transformers to digitally sense currents

- Two temperature sensors can also be used for thermal monitoring

- MODBUS RTU communication with building automation systems

- Trip point can be set based on current flow, current imbalance, temperature

- Current trip timing is based on energy into system after trip set point is reached

- Menu system allows easy adjustment of parameters and set points

- 32 character LCD display

- Selectable number of trips with automatic reset

- Alarm signal

- Can read and write all values over MODBUS, including manual reset

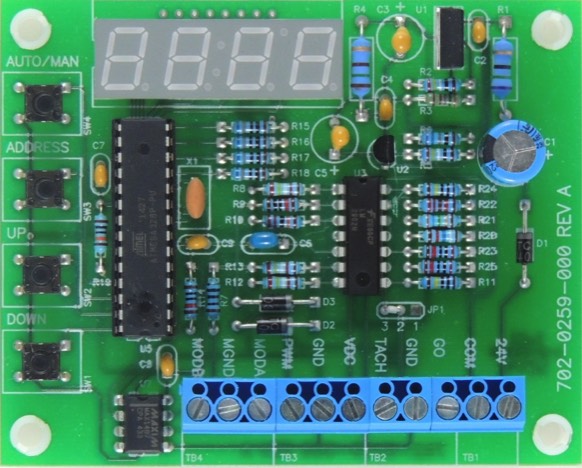

- Control the speed of an ECM motor locally or remotely

- MODBUS RTU communication with building automation systems

- Closed-loop control mode will maintain motor speed independent of loading

- LED display of motor rpm

- PWM and DC outputs plus GO Signal

770-PSC PSC Motor Speed Control (Coming Soon)

- Control the speed of a PSC or shaded pole motor locally or remotely

- MODBUS RTU communication with building automation systems

- Closed-loop control mode will maintain motor speed independent of loading

- Remote sensing of motor rpm

- Easy operation with LCD based menu system

- Motor voltages of 115 to 277 VAC

- Motor currents up to 10A

- For PSC or shaded pole single phase, single speed motors

- Optimizes fan speed to improve system performance and save energy

- For three phase induction condenser fan motors

- Optimizes fan speed to improve system performance and save energy

- For PSC or shaded pole motors

- Low cost manually adjustable proportional speed control

- Voltage ranges from 120 to 480 Volts, current up to 15 Amps

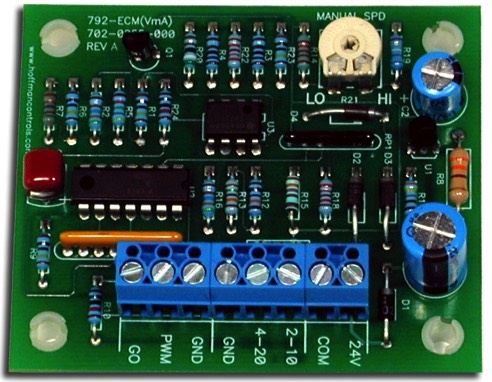

- For EC Motors

- Low cost manually adjustable speed control

- PWM output to motor

- For EC Motors with PWM input

- Allows replacement of discrete speed PSC or EC motors with variable speed EC motors

- Heating and cooling speeds are adjustable

- For EC Motors with PWM input

- Allows replacement of discrete speed ECM with variable speed ECM

- All four speeds are adjustable

- For EC Motors

- Control input is DC voltage or current

- PWM output to motor

- For PSC and shaded pole motors

- Control input is DC voltage 2-10V

- Minimum speed adjustment

- Continuous flow switch

- 115/208-230V, 10 amps